| Purpose: |

The LW type flow switch is mainly used for detecting fluid flow in industrial production processes (such as cooling water, lubricating oil, etc.). This flow switch is directly installed on the tested pipeline to automatically detect all abnormal states caused by various fluid fluctuations and provide them to the control room to ensure the safe operation of production equipment.

| characteristic: |

This flow switch is suitable for slurries or very dirty liquids that cannot be measured by other flow meters.

Can detect fluctuations in liquids with high viscosity.

The flow switch has a simple structure and is fixed without maintenance.

Because its connecting component is a magnetic coupling, there is no leakage.

In addition to on-site display, it can be equipped with on-site alarm display lights, without the need for external power supply or remote switch alarm.

The position of the alarm point can be set and adjusted arbitrarily.

| Main technical parameters: |

Tested medium: liquid (clean slurry, dirty fluid).

● Working pressure: 0.5 0.7 1.0MPa

● Caliber: DN10~150mm

● Medium temperature: 80, 100, 150 ℃

Accuracy: ± 10%

● Contact capacity: Micro switch 220V 5A; Self protective magnetic switch 220V 0.3V

● Power supply: 1) The on-site alarm light does not require a power supply and comes with a 3.6V lithium battery with one unit

2) Remote transmission output requires an external power supply of 220V AC, 24V DC

● Flow range:

|

Caliber (DN) |

Flow range m3/h |

Caliber (DN) |

Flow range m3/h |

|

10 |

0——1 |

50 |

0——14 |

|

15 |

0——2 |

65 |

0——18 |

|

20 |

0——3 |

80 |

0——22 |

|

25 |

0——4 |

100 |

0——28 |

|

32 |

0——6 |

125 |

0——32 |

|

40 |

0——10 |

150 |

0——40 |

| Working principle and structure: |

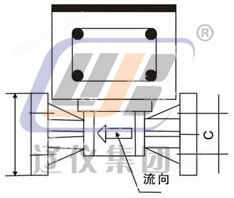

The principle of this flowmeter is to place a right angle damping plate into the liquid, so that the pressure P1 and flow velocity W on the front side increase proportionally by square, while the pressure P2 and flow velocity W on the back side decrease proportionally by square. This P1-P2 is measured by the change in the damping plate, and the flow rate is indicated by the change in the pointer through magnetic force.

The liquid entering the flowmeter from the side indicated by the arrow pushes the damper to fix it in the measuring chamber. The damper, which is always at zero position due to the elasticity of the spring and the angle of the damper, is modified based on the flow rate.

To prevent leakage around the upper connection, the upper connection can be coupled with this pair of magnets. There is an external magnet fixed to the pivot of the pointer axis, which can rotate the pointer together with the internal magnet to prevent leakage.

The motion of the damper is transmitted to the pointer shaft, which has a metal shaft and a fixed internal strong magnet at its top, and then rotates the internal magnet.

| model: |

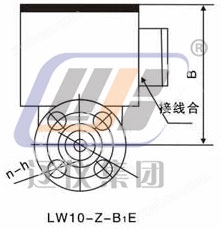

LW XX X XX

LW: Model XX: Caliber

X: Fluid flow direction - Z: from left to right; Y: From right to left; S: From top to bottom; X: from down up

X: Alarm form - A: On site indicator light display; B1: A set of switch outputs; B2: Two sets of switch output

X: Switch form - E: Self protective magnetic switch; F: The micro switch

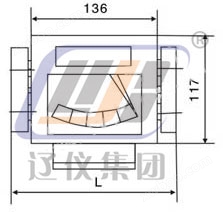

| Appearance: |

|

|

|